Automotive facilities utilize a brake tester to assess the condition of a stationary vehicle’s brake system. This evaluation assesses the brake’s performance and minimizes the dangers that can come from a vehicle having a faulty brake system. Brake testers might just be able to spare a vehicle from disaster. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More Brake Testers Manufacturers

How a Brake Tester Works

Brake testers are essential diagnostic equipment used in automotive workshops, vehicle inspection centers, and by regulatory authorities to evaluate the performance of a vehicle’s braking system. Understanding how a brake tester works is crucial for anyone involved in vehicle safety, fleet management, or automotive maintenance. These devices are designed to quantify the braking force produced by a vehicle, ensuring compliance with safety standards and identifying potential issues before they become hazards on the road.

To begin the brake testing process, the vehicle moves onto the brake tester, positioning its wheels between the two main rollers (in the case of a roller brake tester). The vehicle’s identifying specifications, such as weight and axle configuration, are entered into the brake tester’s control system. The rollers then automatically spin at a calibrated speed, simulating road movement while the vehicle remains stationary. The driver is prompted to apply the brakes at a designated moment, which in turn applies braking force onto the system’s motor and sensors.

While the vehicle itself does not move forward, the brake tester measures the total braking force exerted by each wheel. This is achieved using transducers and advanced weighing systems within the tester mechanism, which capture the reactive force generated during braking. The automated weighing system calculates the vehicle’s braking efficiency as a percentage, comparing the measured braking force to the weight of the vehicle to ensure optimal safety performance.

Many modern brake testers are equipped with digital displays, data logging features, and integration capabilities for vehicle inspection software. These features enable workshops and inspection centers to maintain accurate records, generate compliance reports, and track vehicle maintenance history. Brake testers are a fundamental part of preventive vehicle maintenance, helping reduce the risk of brake failure and supporting legal compliance for commercial vehicles and passenger cars alike.

Types of Brake Testers

There are several types of brake testers commonly used to measure braking effort, efficiency, and balance in motor vehicles. Each type serves specific applications and offers unique advantages, making it important to understand their operational principles and intended use cases. The main types of brake testers include:

Roller Brake Tester

Roller brake testers are the most widely adopted solution for dynamic evaluation of motor vehicle braking systems. These brake testers are standard equipment in professional automotive workshops, vehicle inspection stations, and commercial fleet maintenance facilities. The roller brake tester allows comprehensive testing while the vehicle remains stationary, providing a controlled and repeatable environment for accurate measurement.

The core of a roller brake tester is a robust floor-mounted unit comprising electric motors, two or more sets of heavy-duty rotating rollers, precision braking force transducers, and built-in safety sensors. During a test, the drive rollers rotate the vehicle’s wheels at a low, consistent speed. The operator applies the brakes, causing the wheels to resist the roller movement. The braking force generated is measured by transducers and strain gauges, which detect the reaction force transferred through the system’s mechanical components.

Roller brake testers can measure individual wheel braking forces, total axle braking force, and brake balance between left and right wheels. Modern units may also assess parameters such as brake ovality (indicating warped brake discs or drums), rolling resistance (bind), and, for air-braked vehicles, pneumatic system performance. The data is displayed in real time, providing instant feedback to technicians and supporting detailed inspection reports.

Common applications for roller brake testers include:

- Periodic vehicle inspections – meeting regulatory brake performance standards

- Workshop diagnostics – identifying brake faults, imbalance, or system inefficiencies

- Fleet maintenance – monitoring brake wear and ensuring uniformity across vehicles

- Pre-sale vehicle testing – verifying brake performance before resale

Are you searching for the best roller brake tester for your automotive workshop or inspection facility? Browse our brake tester supplier directory to compare models, features, and pricing.

Plate Brake Tester

Plate brake testers offer an alternative dynamic testing method, particularly valued for their simplicity and minimal moving parts. These units consist of two parallel, floor-mounted plates equipped with sensitive force transducers. During testing, the vehicle is driven at a slow speed onto the plates, and the driver applies the brakes, causing the plates to “slip” slightly in the direction of travel.

The force required to resist this slipping movement is measured by the transducers, allowing calculation of the braking force exerted by each wheel. The system can also assess brake balance between left and right sides by analyzing the voltage output from each force transducer. Plate brake testers are especially useful in situations where space is limited, or where a quick assessment of brake performance is needed without the complexity of roller systems.

Typical use cases for plate brake testers:

- Roadside vehicle inspections – portable and fast assessment of brake condition

- Small workshops – facilities with limited floor space or lower testing volumes

- Commercial fleet spot checks – quick verification of brake balance and efficiency

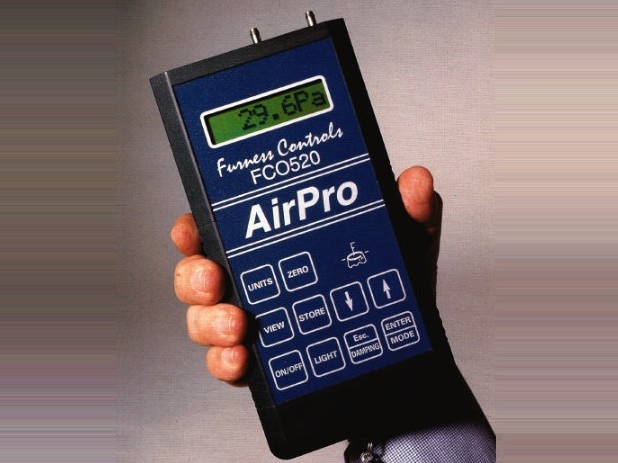

Decelerometer

A decelerometer is a compact, handheld device designed for quick measurement of vehicle braking efficiency during a road test. Functioning similarly to an accelerometer, a decelerometer measures the negative acceleration (deceleration) experienced by the vehicle when the brakes are applied.

To use a decelerometer, the device is securely placed in the vehicle, and the vehicle is then driven on a level, straight stretch of road. The driver applies the brakes firmly, and the decelerometer records the rate of deceleration, which is used to calculate overall brake efficiency. Decelerometers provide a swift, straightforward indication of whether a vehicle’s braking performance meets safety requirements, making them ideal for preliminary checks or where workshop-based equipment is unavailable.

However, decelerometers are generally considered less precise than roller or plate brake testers, as results can be affected by road surface conditions, vehicle load, and driver technique. Low efficiency readings obtained with a decelerometer often prompt further investigation using a roller or plate brake tester for more detailed diagnostics.

When should you choose a decelerometer? If you need a portable, cost-effective brake testing tool for initial assessments or compliance checks, a decelerometer may be the right choice. For full diagnostic accuracy, consider supplementing with a roller or plate brake tester.

Key Considerations When Choosing Brake Testers

When selecting a brake tester for your garage, fleet, or inspection center, several critical factors influence which system will best meet your operational needs. Evaluate the following considerations to ensure you choose the most suitable brake testing solution for your application:

Method of Operation

- Roller brake testers measure the reaction force created as brakes resist rollers rotated by an electric motor, delivering precise, repeatable results in a controlled environment.

- Plate brake testers utilize strain gauges mounted to slip plates, measuring the force required to hold the plate as the vehicle brakes on top of it. This allows for quick, comparative measurement of left/right braking force.

- Decelerometers are placed inside the vehicle, using a pendulum or internal sensor to measure deceleration during braking. This method offers portability but is influenced by external road and load conditions.

Want to see a comparison of brake tester types and their testing principles? Click here for detailed side-by-side analysis.

Brake Test Safety

- Roller brake testing is considered a safe method, as the vehicle remains stationary while the rollers spin underneath the wheels. This reduces risk to workshop staff and nearby vehicles.

- Plate brake testers and decelerometers require the vehicle to be driven and braked on the plates or on the road, which can introduce risks in confined spaces or busy environments.

- Always ensure proper safety protocols are in place and personnel are trained for the specific brake tester being used.

Accuracy and Repeatability of Results

- Roller brake testers provide highly accurate comparative tests, as all vehicle wheels are tested on identical braking surfaces and at constant speeds.

- Plate brake testers also use a consistent surface for all wheels, but may be less precise than rollers in detecting subtle variations in brake force or system faults.

- Decelerometers are less consistent, as results are affected by road surface, gradient, and driver input. Variability can make accurate comparisons challenging.

Adaptability and Application Range

- Roller brake testers can evaluate the complete range of braking force for each axle, from light to full braking, and are suitable for most vehicles, including cars, commercial trucks, and buses.

- Plate brake testers are limited in the range they can test and may not be suitable for high-capacity vehicles or those with complex braking systems.

- Decelerometers cannot test separate axles independently, limiting their diagnostic capability for multi-axle vehicles.

Not sure which brake tester suits your fleet size or vehicle types? Contact our experts for tailored recommendations.

Integration and Data Management

- Modern brake testers often include data connectivity for workshop management software, allowing digital record-keeping and streamlined compliance reporting.

- Evaluate whether your operation would benefit from integration with garage management systems, regulatory databases, or cloud-based vehicle maintenance tracking.

Compliance and Certification

- Ensure the brake tester meets national and international safety standards, such as ISO, ECE, or local inspection authority requirements.

- Look for calibration certificates and regular maintenance support to guarantee ongoing accuracy and legal compliance.

Cost, Service, and Support

- Consider the total cost of ownership, including initial investment, maintenance, calibration, spare parts, and software updates.

- Choose a supplier or manufacturer known for reliable after-sales service, technical support, and readily available consumables.

Advantages and Benefits of Brake Testers

Brake testers deliver a range of operational, safety, and economic benefits for automotive professionals, fleet operators, and regulatory authorities. Understanding these advantages can help you justify the investment and select the right solution for your needs:

- Enhanced road safety: Regular brake testing helps prevent accidents by identifying deteriorating performance before failure occurs.

- Regulatory compliance: Meet legal inspection requirements for commercial vehicles, taxis, buses, and passenger cars.

- Improved diagnostic accuracy: Detect issues such as brake imbalance, uneven wear, rolling resistance, and hydraulic or pneumatic faults.

- Cost savings: Early fault identification reduces the risk of expensive repairs and minimizes downtime.

- Increased resale value: Vehicles with documented brake testing histories are more attractive to buyers and command higher prices.

- Operational efficiency: Streamlined, automated testing processes save time compared to manual assessments.

- Versatility: Roller and plate brake testers can accommodate a wide range of vehicle types, from light passenger cars to heavy-duty trucks and trailers.

- Data management: Integration with workshop management software enables seamless record-keeping and reporting.

Decelerometers, while affordable and portable, provide quick and convenient brake performance checks, particularly for mobile inspection units or roadside enforcement. Plate testers, with fewer moving parts, offer robust and reliable operation with minimal maintenance, and are ideal for workshops with limited space. Roller brake testers, meanwhile, support advanced diagnostics such as air pressure testing, rolling resistance (bind), and detection of ovality in discs or drums, making them the go-to solution for comprehensive brake analysis.

Buyer’s Guide: How to Choose the Right Brake Tester

Choosing the right brake tester involves matching your operational requirements to the capabilities of available systems. Use these steps to guide your purchase decision:

- Assess your vehicle fleet: Consider vehicle types, axle counts, braking systems (hydraulic, pneumatic, electric), and average daily testing volumes.

- Define your testing needs: Will you conduct routine inspections, detailed diagnostics, or both? Do you need a portable solution (decelerometer) or a fixed installation (roller/plate)?

- Evaluate facility space and infrastructure: Ensure you have adequate floor space, power supply, and safe access for the chosen equipment.

- Review integration requirements: Do you need data connectivity, reporting, or integration with workshop management software?

- Consider compliance obligations: Verify that the tester meets all relevant standards and can be calibrated for legal inspections.

- Analyze long-term costs: Factor in purchase price, maintenance, calibration, and potential future upgrades.

Still have questions about finding the best brake tester for your business? Request a free consultation from our product experts.

Choosing the Correct Brake Tester Supplier

Selecting a reputable brake tester supplier is essential for obtaining a reliable, high-quality product and ongoing technical support. When comparing suppliers, consider their experience, service offerings, and product range. Our directory of brake tester suppliers provides detailed company profiles, highlighting areas of expertise, certifications, and customer testimonials. Use our contact form to reach out directly for more information or request a personalized quote.

Additionally, our proprietary website previewer allows you to review each brake tester business’s online presence, helping you identify the most suitable partner for your needs. For bulk inquiries or to contact multiple suppliers at once, use our streamlined RFQ (Request for Quote) form and specify your application, vehicle types, and testing requirements.

- Compare leading brake tester brands and models in one place

- Access technical specifications, compliance documentation, and pricing information

- Read real customer reviews and case studies for each supplier

- Easily request product demonstrations or virtual consultations

Ready to take the next step? Contact our recommended brake tester suppliers now for expert advice and competitive pricing.

Frequently Asked Questions About Brake Testers

What is the difference between a roller brake tester and a plate brake tester?

Roller brake testers use rotating rollers to simulate road movement and measure brake force while the vehicle remains stationary, offering high accuracy and repeatability. Plate brake testers, on the other hand, use slip plates equipped with force transducers to measure braking force as the vehicle is driven onto the plates. Roller testers are preferred for comprehensive diagnostics and legal inspections, while plate testers are valued for portability and quick assessments.

How often should brake testers be calibrated?

Brake testers should be calibrated according to the manufacturer’s recommendations, typically at least once per year or after any major repair or relocation. Regular calibration ensures measurement accuracy and compliance with legal standards.

Can brake testers be used for all types of vehicles?

Most roller and plate brake testers are designed to accommodate a wide range of vehicles, from light passenger cars to heavy-duty trucks and buses. Always verify the maximum axle load, wheelbase range, and compatible braking systems before purchasing. Specialized testers are available for motorcycles, trailers, and off-road vehicles.

What regulations apply to brake testers?

Brake testers used for legal inspections must comply with standards such as ISO 21069, ECE R13, or local regulatory authority requirements. Compliance ensures that test results are recognized for vehicle registration, roadworthiness certification, and fleet management.

How do I maintain my brake tester?

Regular maintenance includes visual inspections, cleaning, lubrication of moving parts (for roller systems), software updates, and periodic calibration. Follow the manufacturer’s maintenance schedule and keep detailed records to ensure long-term reliability and compliance.

Get Expert Help or Request a Quote

Are you looking for the best brake tester for your automotive business, inspection center, or fleet maintenance operation? Our team of industry experts can help you compare products, understand technical specifications, and select the optimal solution for your needs. Whether you require a roller brake tester, plate brake tester, or portable decelerometer, we have you covered with unbiased advice and access to leading suppliers.

Contact us today for a free consultation, detailed product information, or to request a competitive quote. Let us help you make an informed decision and enhance your vehicle safety program with a state-of-the-art brake tester solution.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

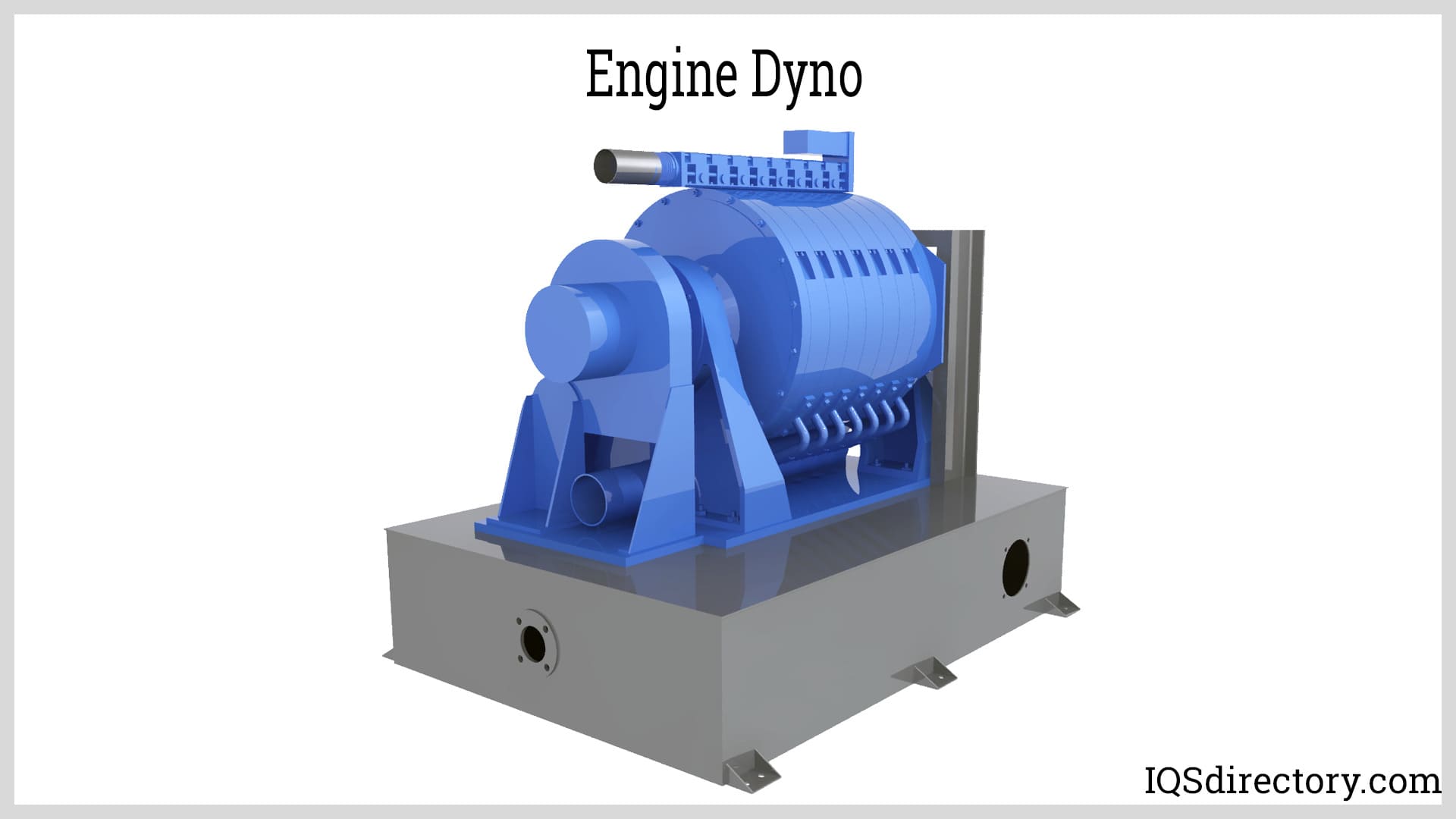

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services