A vital part of the production of any product is testing, which has become an essential component in manufacturing. The data provided by testing is critical for engineers and designers to be able to determine the viability and applicability of their products. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More AC Dynamometer Manufacturers

An important part of the development of testing was the invention of the dynamometer during the first industrial revolution, which provided data regarding the force that a horse could produce. Over the years, the use of dynamometers, AC dynamometers in particular, has become a routine part of the development of electric motors and motors in general.

What is an AC Dynamometer?

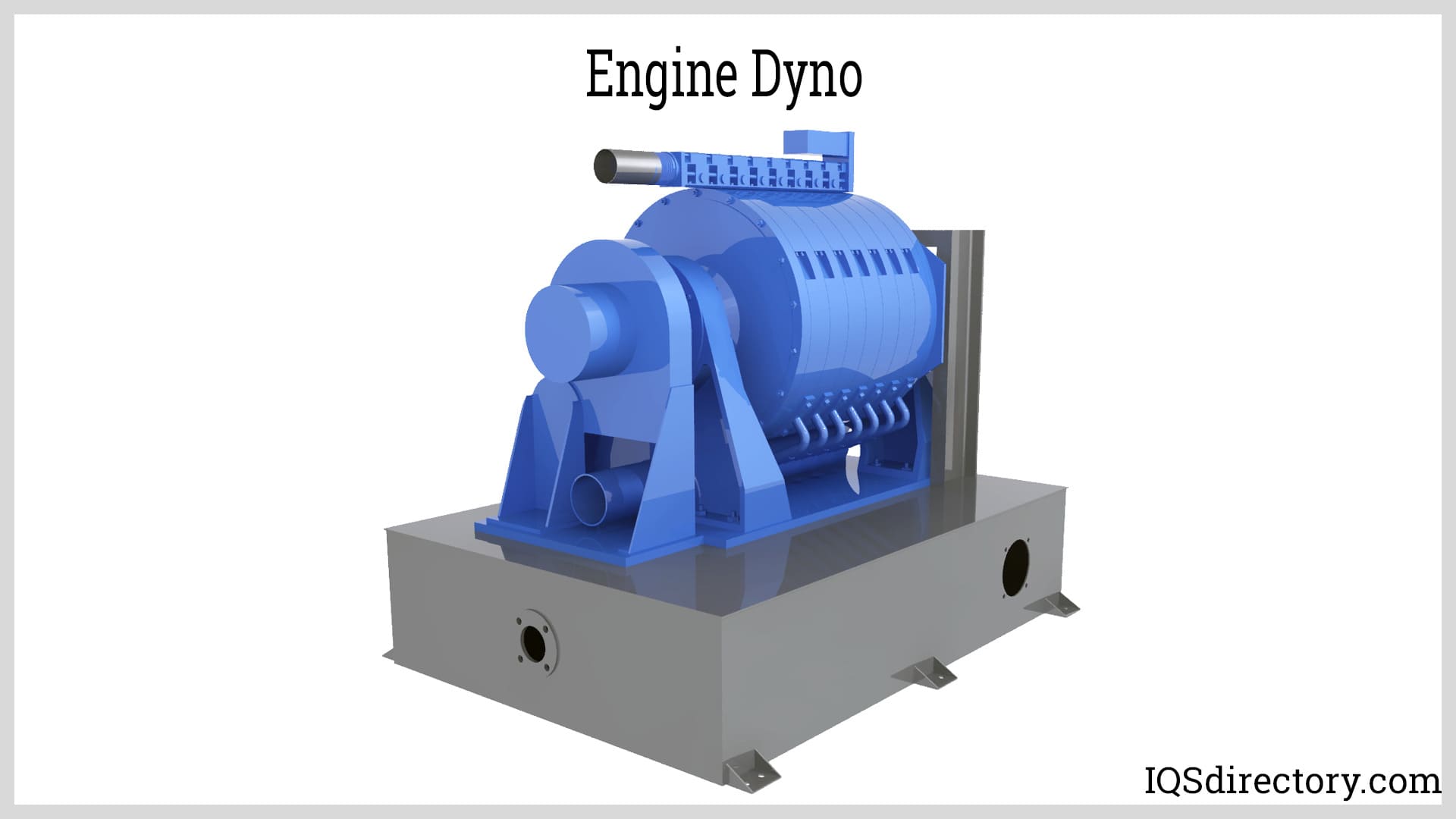

AC dynamometers are complex technical instruments designed to test multiple factors related to motors. They offer a controllable method for examining the features of an engine prior to its being installed in a mechanism. Dynamometers test the RPMs and torque of motors using a set of instruments that are discretely attached to the tested device.

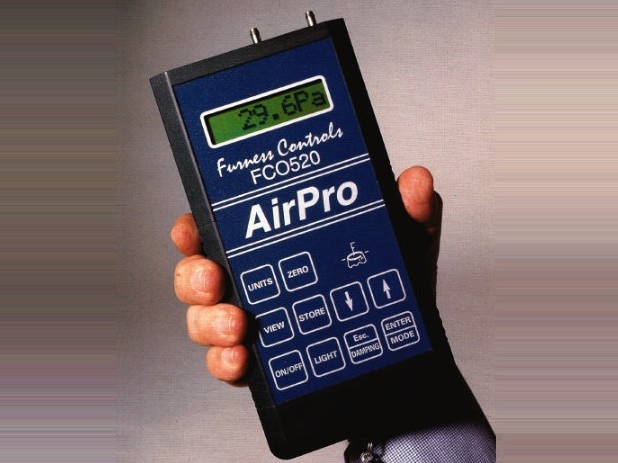

For testing purposes, AC dynamometers are connected to the test motor and are capable of testing temperature, pressure, speed, and torque levels. The device can monitor all aspects of an engine or individual elements, depending on the needs of the researchers. The components of an AC dynamometer include an induction motor, torque sensor, a base, a flange connector, AC converter system, and a dynamometer measuring instrument.

The main reason for testing is to acquire accurate data to make informed decisions. An AC dynamometer is the perfect device since it has an accuracy rating of 90% or greater, which is superior to other testing methods. As any engineer and designer can tell you, accurate data is essential to product development.

Uses for an AC Dynamometer –

As with any testing instrument, the types of data that a dynamometer can provide goes beyond the amount of torque and RPMs. A huge concern of modern-day manufacturers is environmental impact and their ecological footprint, a concern that is shared by their customers.

An assist in determining the environmental factors related to a product can be assessed by a dynamometer, which is capable of measuring an engine’s emissions. A benefit of using a dynamometer is that it does its testing without producing pollution. Motors and engines can be tested in multiple dimensions eliciting any form of contaminants.

Advantages of an AC Dynamometer –

Many of the methods for testing products require a great deal of energy to produce their data. This is not true of a dynamometer, which takes the mechanical energy from the tested instrument and converts it into electrical energy.

As a part of environmental protection, an AC dynamometer does not require a supply of water to operate or for cooling. Thus, no polluted water is sent into the sewage system.

The main benefit of a dynamometer is the reliability and accuracy of the data. The type of data produced offers beneficial information to regulatory agencies for monitoring an engines compliance with environmental regulations.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services