Dynos measure engine performance by running an engine at high speeds for long intervals. Dynos are different than road tests, though, in the vehicle is placed on stationary rollers and can be controlled by a computer. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More Dyno Manufacturers

Some dyno varieties involve a frame that holds the vehicle above engine mounts, rolling cylinders, a heat exchanger and a torque measuring device. Others require hydraulic fluid, water or oil to function. Modern dynomometers are able to graph the performance of an engine in terms of its maximum rotary speed, torque capacity and maximum power absorption. In some cases, they can also provide analyses of emissions and reaction time. Dyno users can interface with their equipment through control consoles, computers or remote controls.

Dynomometers are used to measure the RPMs and torque for gearboxes, belt or chain drives, fluid power systems, gas or diesel systems, turbines, transmissions and other applications. They are most commonly used in the automotive industry but are also applied in aerospace, marine and industrial processes.

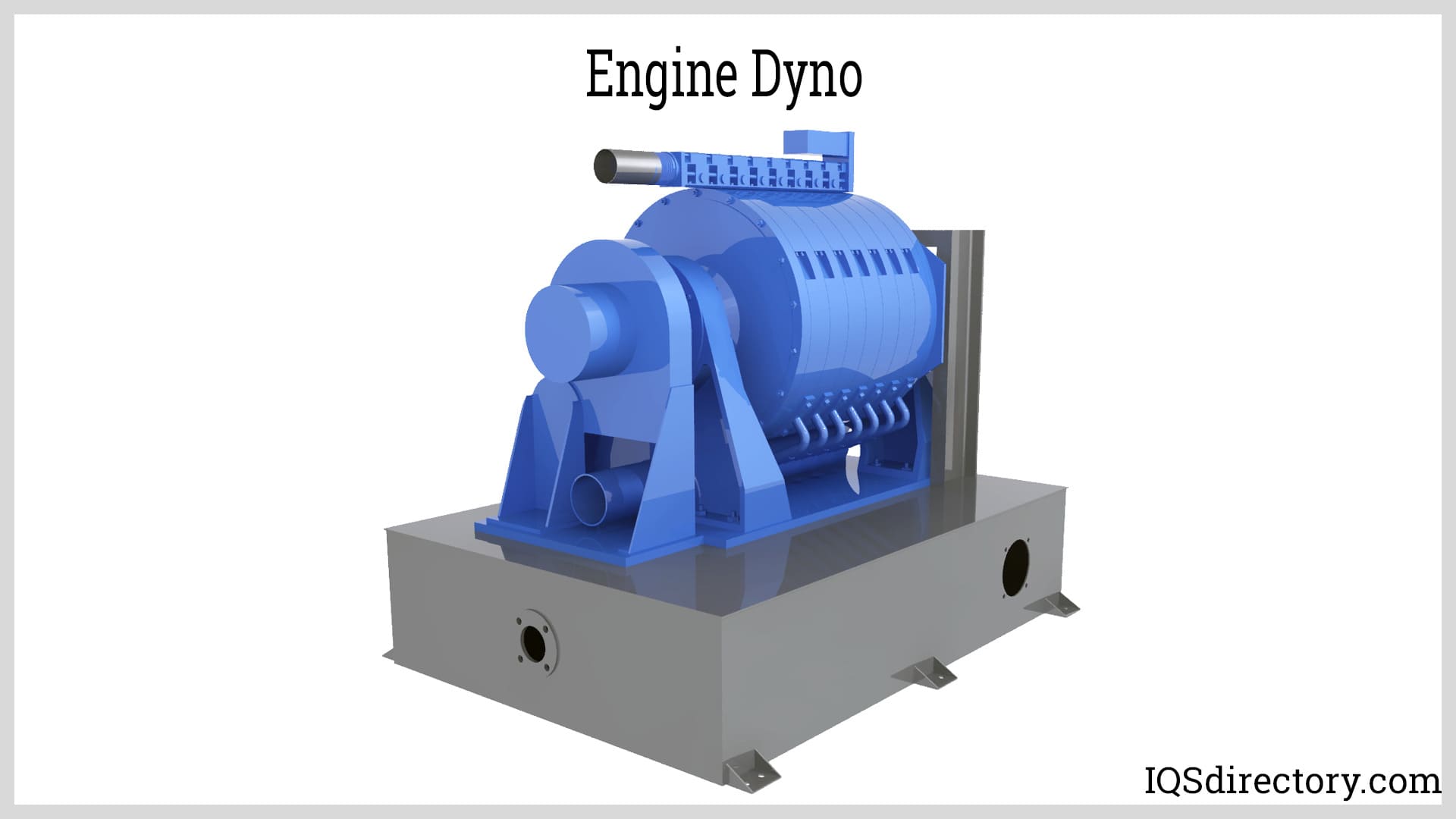

Chassis and engine dynomometers are the most common dyno varieties. Chassis dynos measure an engine's performance based on the speed and nature of the rotation of the wheels that the engine powers; engine dynos measure engine performance directly.

In the case of chassis dynomometers, a vehicle is placed on a frame and placed on rollers. Once secured, a computer starts the vehicle's engine remotely. The computer measures how quickly the rollers rotate and, along with factoring in the weight of the rollers, determines the engine's performance.

Chassis dyno readings can be 15% to 20% lower than readings taken by engine dynomometers because the chassis dynamometer reading process causes energy losses due to friction throughout the drivetrain. In engine dynos, a torque measuring device is connected to the crankshaft or flywheel, and a lubricant may be used to reduce friction and heat generation. Dynos are often used to test new engines or to examine engines during diagnostic testing.

Calibration Services

Calibration Services Clean Rooms

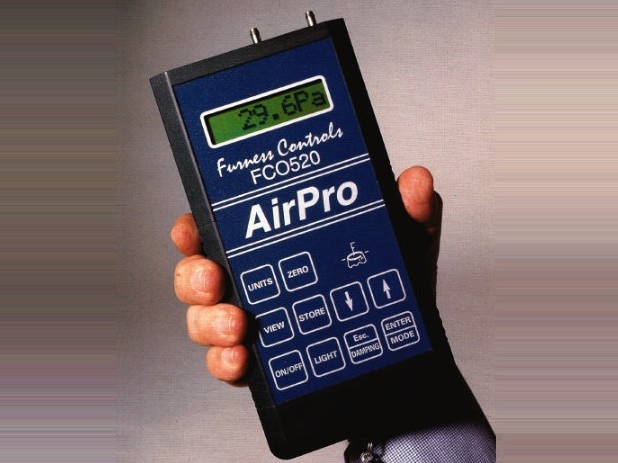

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services