Dynamometers, or “dynos” for short, are devices for measuring force, torque (moment of force), or power. For instance, the power generated by a motor, engine, or any rotating prime mover may be determined by simultaneously measuring rotational speed (rpm) and torque. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More Dynomometer Manufacturers

What is a Dynamometer?

A dynamometer—often referred to as a dyno—is a precision instrument used to measure force, torque, or power generated by engines, motors, or other rotating devices. Dynamometers play a critical role in a wide range of industries, from automotive manufacturing and research to aerospace, marine, and industrial machinery. By providing accurate data on an engine or motor’s performance, dynamometers empower manufacturers, engineers, and technicians to analyze efficiency, diagnose issues, certify compliance, and improve design.

Did you know? Dynamometers are not just for measuring engines; they can also be used to calculate the power and torque required to operate driven machinery such as pumps, compressors, or industrial fans. In such cases, a driving dynamometer (also called a motoring dynamometer) is used to supply power to the device under test.

There are two main categories of dynamometers: absorption (passive) and active (universal). An absorption dynamometer absorbs energy produced by the device under test and dissipates it, often as heat. Conversely, an active or universal dynamometer can both absorb and supply power, enabling more flexible testing scenarios for engines and electric motors.

How a Dynamometer Works

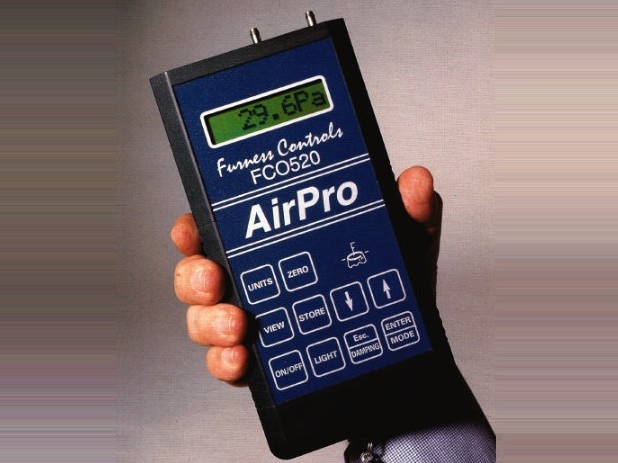

Dynamometers function by measuring, recording, and analyzing a variety of parameters associated with a power source. At their core, dynos measure the force, torque, or rotational speed (RPM) produced by an engine, electric motor, or other machinery. Modern dynamometers are equipped with advanced sensors, data acquisition systems, and software for real-time monitoring and analysis.

Depending on the specific design and application, dynamometers can measure:

- Torque (the rotational force produced by an engine or motor)

- Power output (usually expressed in horsepower [HP] or kilowatts [kW])

- Rotational speed (RPM)

- Compressive and tensile force (for material or structural testing)

- Mechanical efficiency and losses

In the automotive industry, dynamometers are essential for measuring engine torque, power curves, fuel efficiency, emissions, and vehicle performance under simulated road conditions. Engineers use this data to optimize engine management systems, calibrate fuel injection, and ensure regulatory compliance.

Considerations when Selecting a Dynamometer

Choosing the right dynamometer system is a critical decision that impacts the accuracy and efficiency of your testing processes. The following considerations are crucial when selecting a dynamometer for your application:

- Maximum power absorption: The highest rotational power the dyno can safely absorb. This is dictated by the braking or absorption technology used (such as eddy current, hydraulic, or electrical absorption).

- Torque capacity: The peak torque the dynamometer’s shaft and components can handle continuously without risk of failure.

- Maximum rotary speed: The top safe operational speed (RPM) under load. Exceeding this can damage both the dyno and the test device.

- Maximum linear speed: Relevant for dynamometers testing linear actuators, conveyors, or similar machinery.

- Control and data acquisition features: Look for systems with advanced data logging, real-time monitoring, and integration capabilities with other testing equipment.

- Application compatibility: Ensure the dynamometer is suitable for your specific engine, motor, or device (e.g., internal combustion engine, electric vehicle motor, industrial machine).

- Safety features: Overload protection, emergency shutoff, and enclosure standards for operator safety.

- Budget and total cost of ownership: Weigh up-front costs versus long-term reliability, maintenance, and support.

Wondering which dynamometer best fits your needs? Ask yourself: What is the maximum power and torque of the device I need to test? Will I be testing engines, electric motors, or complete vehicles? Do I require advanced data analysis and software integration? Answering these questions will help you narrow down your options.

Types of Dynamometer

There are numerous types of dynamometers, each engineered for specific applications, measurement requirements, and industries. Here’s an overview of the most common dynamometer types:

Rope Brake Dynamometers

- Rope brake dynamometers are simple mechanical devices for measuring the braking power of an engine. They use ropes wound around a rotating drum attached to the output shaft. One end of the rope is connected to a spring balance, while the other is attached to a loading weight or lever. By measuring the tension difference, torque and power output can be calculated.

- Commonly used in educational labs and for basic engine testing where high precision is not required.

Chassis Dynamometers

- Chassis dynamometers (or rolling road dynos) test complete vehicles by having the drive wheels rest on rollers. The dynamometer simulates real-world driving conditions, allowing measurement of wheel power, torque, acceleration, and emissions—all without removing the engine from the vehicle.

- Ideal for automotive R&D, performance tuning, emissions testing, and quality assurance.

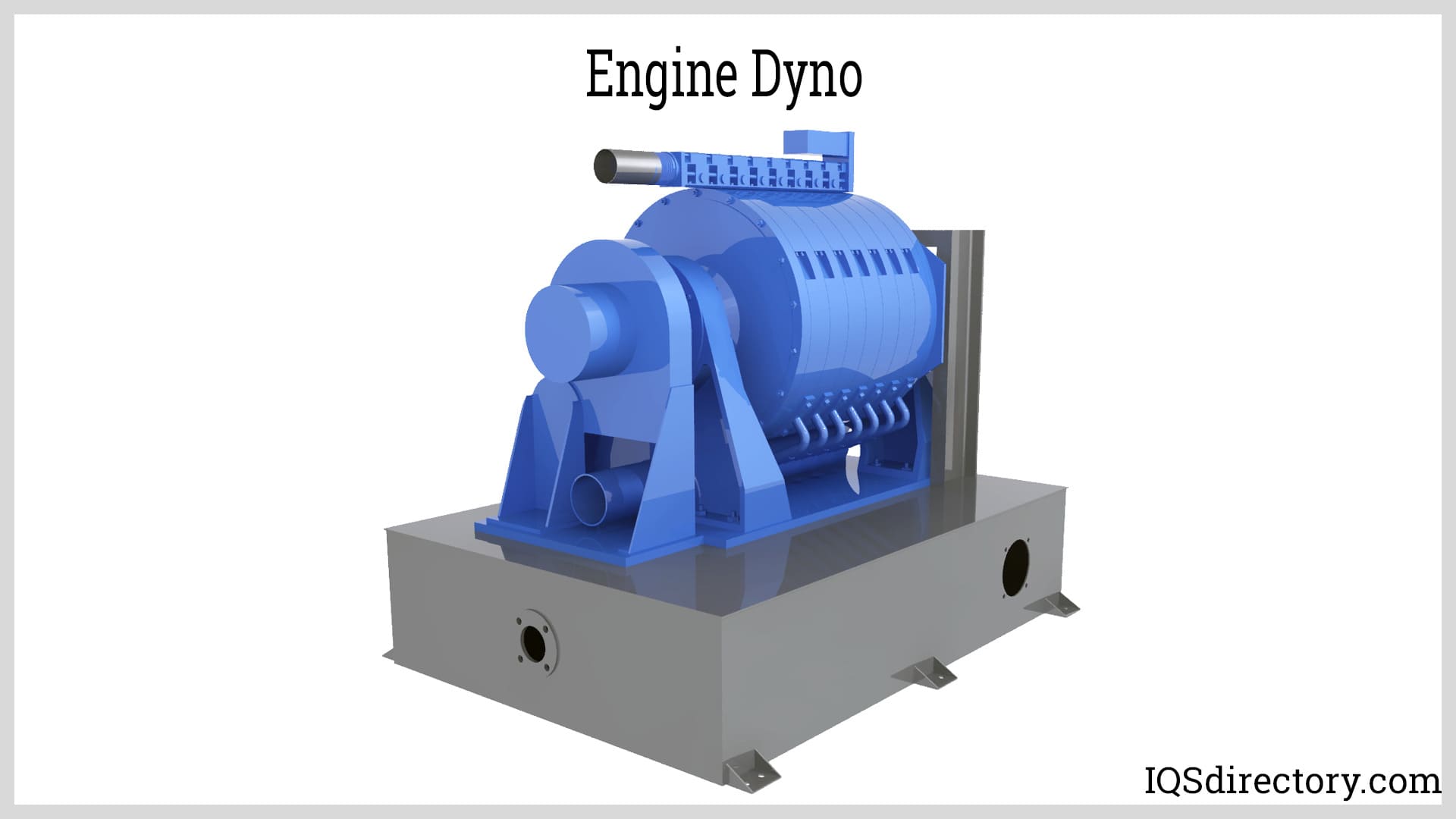

Engine Dynamometers

- Engine dynamometers measure power and torque directly from the engine's output shaft, independent of the vehicle. These systems can be highly accurate, featuring both analog gauges and digital data acquisition for precise, repeatable results.

- Widely used in engine development, certification, and durability testing.

Fluid Dynamometers

- Fluid (hydraulic) dynamometers use fluid resistance—typically water or oil—to absorb energy from the engine or motor being tested. Operators control the absorption characteristics by adjusting fluid properties such as temperature, density, and viscosity.

- Suitable for medium to high power applications, especially in marine, industrial, and engine test benches.

Universal Dynamometers

- Universal (active) dynamometers can both absorb and supply energy, enabling more complex test cycles. Equipped with sensors for speed, power, and torque, they are ideal for applications requiring motoring and braking modes, such as electric vehicle drivetrain testing.

Water Brake Dynamometers

- Water brake dynamometers are a popular type of hydraulic absorption dyno. They use water to provide the resistance needed to absorb engine power, making them suitable for continuous, high-power testing applications.

- Common in engine development, marine propulsion testing, and industrial applications.

- Note: These dynos cannot drive the engine—they only absorb power.

- Learn more about dyno manufacturers.

AC Dynamometers

- AC dynamometers employ AC motors or generators to act as both absorbers and drivers. These universal dynamometers are at the forefront of modern testing technology, offering precise control, rapid response, and high efficiency.

- Frequently used in racing engine testing, electric vehicle research, and advanced automotive labs.

Driving Dynamometer

- Driving dynamometers supply power to the device under test (such as a pump or compressor) to determine the required input for operation. They typically include a motor, measurement sensors, and digital monitors to record torque, speed, and power.

- Ideal for characterizing pumps, fans, and machinery where motoring capability is necessary.

Absorption Dynamometers

- Absorption dynamometers are designed to absorb and dissipate the energy generated by the device being tested. Energy may be absorbed via electrical, hydraulic, or frictional means (such as a Prony brake).

- Choose this type for straightforward power measurement where energy recovery isn’t required.

Hydraulic Dynamometer

- Hydraulic dynamometers operate by dissipating the absorbed power through fluid friction. An inner rotating impeller is coupled to the test device; as the impeller turns, it agitates water or oil, converting mechanical energy into heat.

- Well-suited to high-power engine and industrial testing environments.

Prony Brake Dynamometer

- Prony brake dynamometers are classic friction-based devices. They use wooden blocks clamped against a rotating pulley to create resistance. By measuring the force required to hold the blocks in place, torque and power can be directly calculated.

- Simple, cost-effective, and still used for low-power laboratory demonstrations and calibration tasks.

Eddy Current Dynamometer

- Eddy current dynamometers use electromagnetic induction to provide smooth, adjustable resistance. A spinning metal disc or drum passes through a magnetic field, generating eddy currents that act as a braking force. The resulting heat is dissipated, and the braking force is precisely controlled.

- Preferred for automotive, engine, and electric motor testing where rapid, repeatable load control is essential.

Applications of Dynamometers

Dynamometers are versatile tools with a multitude of industrial and research applications. Their primary function is to measure the power, torque, and efficiency of engines, motors, and mechanical systems, but their uses extend much further.

- Automotive testing: Used to certify horsepower, torque, and emissions for regulatory compliance, performance tuning, and engine development.

- Emissions testing: In regulatory cycles defined by organizations like the U.S. EPA and CARB, chassis and engine dynos simulate real-world driving to measure pollutant output and fuel consumption.

- Electric vehicle and hybrid drivetrain testing: Evaluate battery, motor, and inverter performance, as well as regenerative braking systems.

- Industrial machinery testing: Assess performance and energy efficiency of pumps, compressors, turbines, and generators.

- Research and development: Conduct experimental studies on combustion, tribology, and mechanical losses.

- Quality assurance: Validate that engines, motors, and powertrains meet manufacturer specifications before delivery.

- Material and structural testing: Use specialized dynamometers to measure tensile and compressive strength for engineering and construction materials.

- Marine and aerospace applications: Analyze propulsion systems, turbines, and auxiliary power units under simulated operating conditions.

Interested in how a dynamometer can enhance your testing process? Explore use cases such as optimizing vehicle fuel efficiency, verifying electric motor output, or simulating heavy-duty industrial loads.

Advantages of a Dynamometer

Why invest in a high-quality dynamometer? Here are some of the top benefits of using a dynamometer in your testing and development workflows:

- No special calibration required: Modern dynos are factory-calibrated, ensuring accurate and reliable data straight out of the box.

- Enhanced safety: Built-in safety features protect both personnel and equipment during high-power or high-torque testing.

- Minimized risk of damage: Controlled, repeatable testing reduces the chance of damaging expensive prototypes or engines.

- Superior measurement accuracy: Obtain precise readings of power, torque, RPM, and efficiency, essential for R&D and compliance.

- Versatility: A wide selection of dynamometer types supports a diverse range of applications, from small motors to large industrial engines.

- Data-driven decision making: Real-time data acquisition and analysis accelerates development cycles and helps you troubleshoot issues faster.

- Regulatory compliance: Meet emissions, safety, and performance standards confidently with repeatable, certified testing.

- Optimized product development: Shorten time-to-market and improve product quality by validating designs under controlled conditions.

Looking to improve your testing lab’s capabilities? Consider upgrading to a digital or computer-controlled dynamometer for advanced data analysis, remote monitoring, and automated test routines.

Key Decision Factors When Purchasing a Dynamometer

Before investing in a dynamometer, review these essential decision points to ensure you select the right equipment for your needs:

- Type of device under test: Are you testing internal combustion engines, electric motors, full vehicles, or industrial machinery?

- Required measurement range: Ensure the dyno’s power, torque, and speed specifications match your application.

- Testing environment: Consider lab, production line, or field testing scenarios—each may require different features or ruggedization.

- Integration with existing systems: Look for compatibility with your data acquisition, automation, or control platforms.

- Ease of maintenance and support: Opt for reputable manufacturers with robust technical support and spare parts availability.

- Future-proofing: Choose expandable systems that can accommodate evolving testing needs, such as electric vehicle powertrains or emissions regulations.

Need help choosing? Ask a dynamometer expert: What is the best dyno for high-performance automotive tuning? How can I automate emissions testing? What features should I look for in a dynamometer for electric motor testing?

Selecting the Right Dynamometer Company

To ensure you achieve the best results when purchasing dynamometers, it’s vital to compare multiple dynamometer suppliers and manufacturers. Use our comprehensive dynamometer company directory to review each supplier’s business profile, technical capabilities, and industry experience. Each company page features an overview of their specialties, product lines, and a convenient contact form for direct inquiries or to request a quote.

Looking for a quick way to compare suppliers? Use our patented website previewer to explore each manufacturer’s website and product offerings. Once you’ve identified potential partners, our streamlined RFQ (Request for Quote) form lets you contact several companies simultaneously, saving you time and ensuring you receive competitive pricing and support.

When evaluating dynamometer manufacturers, consider their expertise with your specific application (e.g., automotive, industrial, marine, or aerospace), their range of dynamometer types, after-sales support, calibration services, and their reputation for innovation and reliability. Don’t hesitate to ask for references, case studies, or a demonstration of their systems in action.

Ready to take the next step? Request a quote for your next dynamometer project or contact our team for guidance on selecting the perfect dyno solution for your application.

Frequently Asked Questions About Dynamometers

- What is the difference between an engine dynamometer and a chassis dynamometer?

An engine dynamometer measures power and torque directly from the engine’s output shaft, while a chassis dyno measures at the wheels, reflecting drivetrain losses and real-world vehicle performance. - How do I calibrate a dynamometer?

Most modern dynamometers come factory-calibrated, but periodic verification and calibration using traceable weights or reference engines are recommended for critical applications. - Can dynamometers test electric motors and hybrid drivetrains?

Yes, specialized dynamometers are designed for electric motor and hybrid system testing, with features such as regenerative braking simulation and high-speed data acquisition. - What are the maintenance requirements for a dynamometer?

Maintenance varies by type, but generally includes regular inspection, lubrication, sensor calibration, and software updates. Consult your manufacturer for a recommended schedule. - Where can I find reputable dynamometer manufacturers?

Search our dynamometer supplier directory for trusted companies specializing in your field.

Still have questions? Contact our dynamometer experts for personalized advice and recommendations.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services