An eddy current dynamometer is an electro-mechanical energy conversion machine that changes mechanical energy to electrical energy. It utilizes Faraday’s Law of electromagnetic induction as a working principle. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More Eddy Current Dynamometer Manufacturers

What is an Eddy Current Dynamometer?

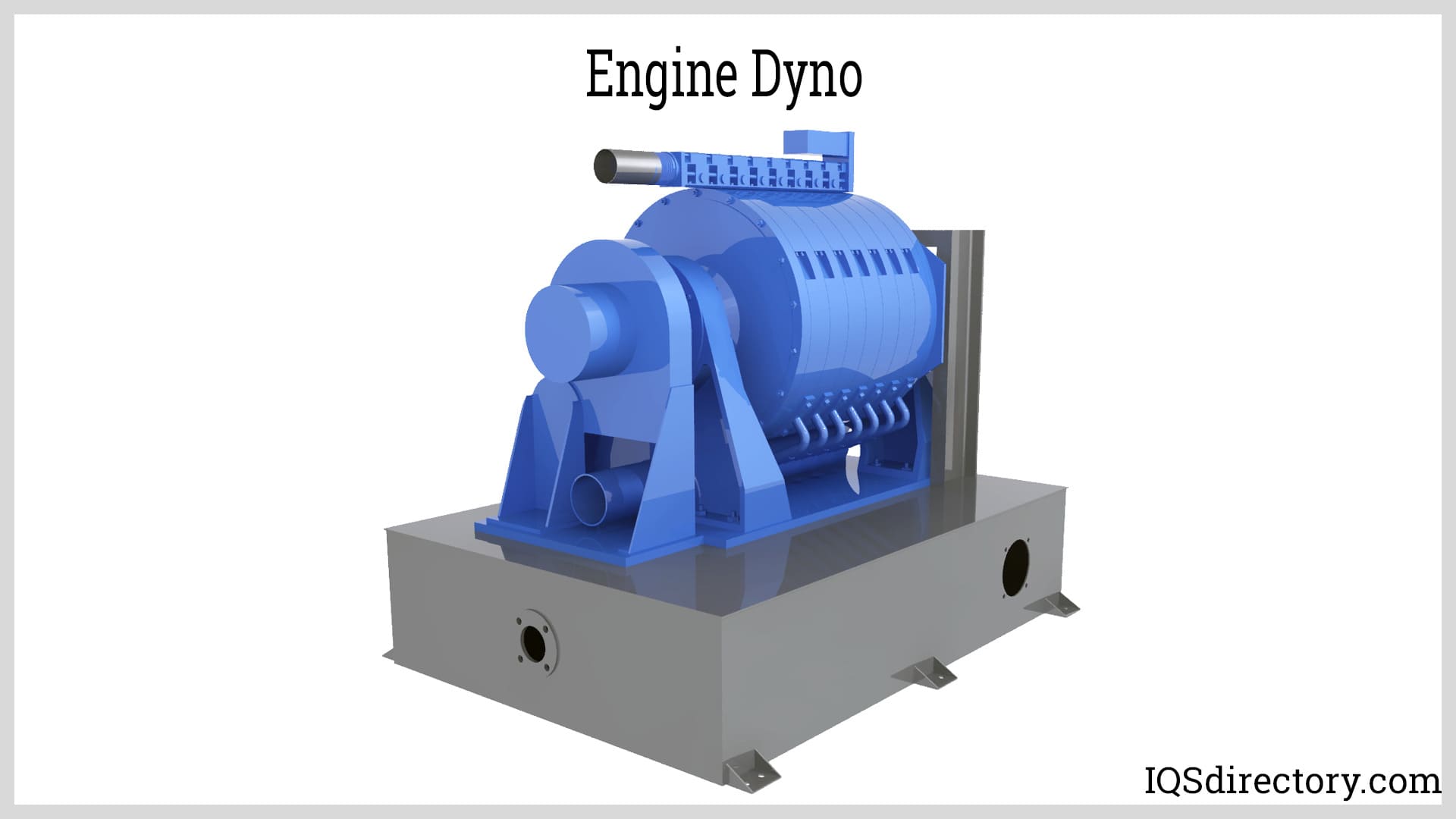

An eddy current dynamometer is a type of absorption dynamometer used primarily to measure the power output, torque, and rotational speed of engines and motors in a highly accurate and efficient manner. This advanced piece of testing equipment operates based on the principle of electromagnetic induction and is widely implemented in automotive, aerospace, industrial, and research applications. Its core assembly comprises a stator—fitted with windings securely placed in stator slots—and, in the case of high-capacity models, three-phase windings for enhanced performance and flexibility.

The eddy current dynamometer is an essential tool for evaluating engine performance, conducting motor testing, and providing precision torque measurement in various test benches and laboratories. By offering non-contact braking and accurate force measurement, it helps engineers, researchers, and manufacturers optimize product design, ensure compliance with regulatory standards, and perform endurance and quality control tests.

Are you searching for the most precise way to measure engine torque or power output? Wondering how eddy current dynamometers compare to other types of dynamometers or brake systems? Read on for a comprehensive guide to eddy current dynamometer technology, specifications, applications, and selection tips.

How an Eddy Current Dynamometer Works

The operational principle of the eddy current dynamometer is rooted in Faraday’s Law of Electromagnetic Induction. When a conductor moves relative to a magnetic field, an electromotive force (EMF) is induced in the conductor. This phenomenon, referred to as a dynamically induced EMF, forms the basis of eddy current dynamometer function.

In this system, the stator poles are excited by a DC supply, which energizes the stator windings and generates a magnetic field. For three-phase devices, a three-phase supply produces a rotating magnetic field within the stator coils. Upon activation, the prime mover (engine or motor under test) drives the rotor, causing it to rotate within this magnetic field.

Importantly, the stator’s magnetic field remains stationary due to the DC excitation. As the rotor (made of non-magnetic, electrically conductive material) spins through this magnetic field, eddy currents are induced within its body. These induced currents interact with the magnetic field to produce a resistive (braking) force that opposes the rotor’s motion. The magnitude of this force is directly proportional to the strength of the magnetic field and the speed of the rotor.

Key Point: No physical contact occurs between the braking mechanism and the rotor, resulting in minimal wear, low friction, and precise control over braking force—making eddy current dynamometers ideal for high-accuracy, repeatable testing environments.

Interested in the science behind eddy current brakes? Looking to understand the advantages of electromagnetic versus mechanical dynamometer designs? Explore our in-depth technical resources or contact a specialist for expert advice.

Typical Specifications of Eddy Current Dynamometers

When evaluating eddy current dynamometer specifications, it’s essential to consider features that impact testing accuracy, operational reliability, cooling requirements, and compatibility with your specific application. Typical specifications include:

- Maintenance: Requires clean water circulation for cooling, free from contaminants or debris to prevent fouling and maintain performance.

- Cooling Water Pressure: Operates with a cooling water pressure range of 0.2 Mpa to 0.4 Mpa, ensuring effective heat dissipation during prolonged test cycles.

- Outlet Water Temperature: Designed to maintain outlet water temperature below 932 °F (500 °C), safeguarding system integrity and preventing overheating.

- Bidirectional Operation: Capable of functioning in both right- and left-handed directions, supporting both clockwise and counterclockwise rotation.

- Torque Measurement Accuracy: Delivers near-exact torque measurement with ±4% accuracy in the 6 kW to 100 kW range and exceptional ±0.2% precision for 160 kW and above.

- Speed Measurement: Speed precision rated at ±1 rpm, enabling high-fidelity performance monitoring and rapid response to dynamic load changes.

Pro Tip: Always verify the compatibility of your dynamometer’s electrical and cooling specifications with your testing facility’s infrastructure to ensure uninterrupted operation and accurate results.

Looking for specific eddy current dynamometer models or performance data? Need help with sizing or capacity calculations? Use our manufacturer comparison tool or consult our buying guide for detailed selection criteria.

Eddy Current Dynamometer Construction

The construction of an eddy current dynamometer is engineered for robustness, precision, and efficient heat dissipation. The primary components include:

- Non-Magnetic Steel Rotor: Mounted on the shaft of the device under test, the rotor is fabricated from highly conductive, non-magnetic steel. Its rotation within the stator is the source of eddy current generation.

- Cast Iron Stator: Encasing the rotor, the stator is constructed from smooth cast iron and houses the excitable coil. The gap between rotor and stator is minimal, maximizing electromagnetic interaction while minimizing losses.

- Excitable Coil: Energized by an external DC supply, this coil produces the magnetic field necessary for eddy current formation within the rotor.

- Torque Arm with Spring: The stator is mounted to allow free swinging and is equipped with a torque arm attached to a spring. This mechanism permits precise measurement of the reaction force (torque) generated by the braking action.

Features of an Eddy Current Dynamometer

Compared to traditional mechanical dynamometers, the eddy current variant offers unique features that enhance its value for advanced testing and measurement scenarios:

- Non-Contact Braking: The eddy current effect produces a braking force that acts without any physical contact, significantly reducing wear and maintenance requirements.

- Direction of Eddy Currents: The direction of the induced eddy currents opposes changes in magnetic flux, providing a stable and controllable braking effect.

- Low Losses: With no direct contact between conductors and magnetic fields, rotational losses are minimized, resulting in higher test efficiency and lower operational costs.

- Direct Torque Measurement: The inclusion of a torque arm and pointer allows real-time monitoring of torque output, facilitating accurate calculations of power (Power = Speed × Torque).

- Built for Repeatability: The rigid construction and non-contact nature ensure repeatable, reliable results even in extended or high-cycle testing operations.

Wondering how eddy current dynamometers can improve your engine or motor testing process? Curious about integration with automated test benches or data acquisition systems? Contact our technical specialists or explore our resources on application-specific solutions.

Applications of an Eddy Current Dynamometer

Eddy current dynamometers are recognized for their exceptional suitability in a wide array of industrial, automotive, research, and development environments. Their key applications include:

- Automotive Testing: Used extensively for evaluating engine performance, transmission components, and drive systems in automotive R&D and production quality control.

- Gas and Water Turbines: Ideal for measuring torque and rotational speed in turbines, supporting efficiency optimization and reliability studies.

- Internal Combustion Engine Testing: Provides rapid and repeatable assessment of combustion engine power output, supporting emission testing, endurance trials, and certification processes.

- Electric Motor Testing: Suitable for assessing small to mid-sized electric motors in industrial automation, HVAC, and appliance manufacturing.

- Renewable Energy Systems: Applied in wind turbine research, generator testing, and energy conversion studies.

- Educational and Training Labs: Used in technical institutes and universities for hands-on learning in mechatronics, electrical engineering, and automotive technology.

Looking to optimize your test bench setup? Our experts can help you match the right eddy current dynamometer to your specific application, whether it’s for high-speed, high-torque, or multi-axis testing scenarios.

What industries benefit most from eddy current dynamometer technology? How can you adapt dynamometer systems for specialty testing needs? Browse our application library or submit your technical query for customized advice.

Advantages of an Eddy Current Dynamometer

Eddy current dynamometers offer a range of significant advantages over mechanical and hydraulic alternatives, including:

- Precise Control: Enables fine-tuned control of braking force and load, ideal for dynamic load simulations and transient response testing.

- Rapid Response Times: Low rotational inertia allows for quick load changes, supporting high-frequency data sampling and automated test cycles.

- Stable and Repeatable Measurement: Delivers consistent, reproducible results across a wide range of operating conditions.

- High Efficiency: Minimal frictional losses result in higher overall test bench efficiency and reduced energy consumption.

- Low Maintenance: The absence of friction surfaces and reduced wear translate to less downtime and lower lifetime maintenance costs.

- Simple Integration: Compact, modular design supports integration with modern data acquisition systems, PLCs, and automated test rigs.

- Safe Operation: Enclosed construction and external cooling systems enhance operator safety and facility compliance.

- Reduced Copper Loss: The design avoids large windings, resulting in lower copper losses and improved thermal stability.

- Bidirectional Capability: Can be used for both clockwise and counterclockwise rotation, supporting a broad range of test requirements.

Comparing eddy current dynamometers to other dynamometer types? Need help justifying your investment? Explore our dynamometer buying guide or contact our team for ROI calculations and technical comparisons.

Disadvantages of Eddy Current Dynamometer

While eddy current dynamometers are well-suited for many industrial and research applications, it’s important to consider some limitations:

- No Torque at Zero Speed: Unable to generate braking torque when the rotor is stationary, making them unsuitable for applications that require holding torque at zero rpm (e.g., static engine calibration).

- Limited Low-Speed Reliability: Performance and accuracy may diminish at extremely low speeds, reducing reliability for certain applications.

- Cooling System Dependence: Requires reliable water cooling to prevent overheating, increasing system complexity and facility requirements.

- Higher Initial Cost: Advanced models may have higher upfront costs compared to basic mechanical or hydraulic alternatives, though operational savings often offset this over time.

- Electromagnetic Interference: Strong magnetic fields may require shielding or special installation practices in sensitive environments.

Is an eddy current dynamometer the right fit for your testing needs? Want to learn more about alternatives or hybrid solutions? Consult our experts for tailored recommendations.

Key Considerations When Selecting an Eddy Current Dynamometer

Choosing the right eddy current dynamometer for your operation involves evaluating several critical factors to ensure it meets your technical and operational requirements:

- Power and Torque Range: Match the dynamometer’s rated capacity to your engine or motor’s maximum output for safe and accurate measurement.

- Speed Range: Consider the minimum and maximum rpm supported to ensure compatibility with your test objects.

- Cooling Requirements: Assess your facility’s ability to provide reliable water cooling and manage thermal loads during prolonged testing.

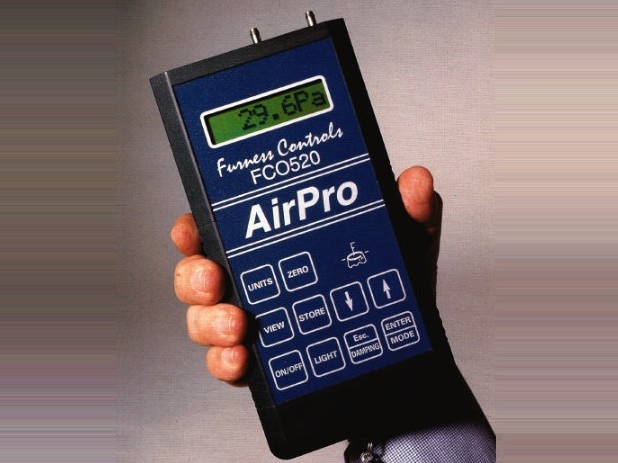

- Data Acquisition Capabilities: Look for integrated sensors, data logging, and connectivity with your existing test bench infrastructure.

- Physical Footprint: Ensure the dynamometer fits within your available lab or production space, factoring in access for maintenance and connections for utilities.

- System Integration: Evaluate support for automation, remote control, and compatibility with PLCs or PC-based test systems.

- Budget and Total Cost of Ownership: Consider not just the initial investment but also maintenance costs, energy consumption, and long-term reliability.

- Manufacturer Support: Prioritize suppliers with strong technical support, spare parts availability, and training resources.

What questions should you ask an eddy current dynamometer supplier? How do you compare quotes and feature lists? Check our comparison checklist for a step-by-step evaluation guide.

Choosing the Correct Eddy Current Dynamometer Manufacturer

To achieve the best results when purchasing an eddy current dynamometer, it’s vital to evaluate and compare leading manufacturers and suppliers. Our directory of eddy current dynamometer manufacturers provides a comprehensive resource for this process. Each manufacturer profile highlights their core competencies, product lines, and unique selling points, as well as offering direct contact forms for inquiries and requests for quotes (RFQs).

How do you choose the best supplier for your application? Here are the essential steps:

- Review manufacturer expertise and product specialization using our patented website previewer.

- Compare product specifications, available models, and application case studies.

- Assess after-sales support, warranty coverage, and availability of spare parts.

- Use our streamlined RFQ system to request quotes from multiple suppliers with a single form, saving time and ensuring competitive pricing.

- Seek recommendations, read customer reviews, and evaluate supplier responsiveness to technical questions.

Ready to request a quote or need further assistance? Visit the manufacturer directory or contact our technical advisors for personalized guidance in selecting the ideal eddy current dynamometer for your needs.

Frequently Asked Questions about Eddy Current Dynamometers

- What makes eddy current dynamometers ideal for automotive testing?

Their rapid response, high accuracy, and non-contact braking make them the preferred option for engine and transmission performance evaluation. - Can I integrate an eddy current dynamometer with my data acquisition system?

Yes, most modern models support advanced connectivity, enabling seamless integration with DAQ systems, PLCs, and automated test benches. - What maintenance does an eddy current dynamometer require?

Routine inspection of the cooling system, stator windings, and calibration checks ensure long-term reliability and performance. - How do eddy current dynamometers compare to hydraulic or mechanical types?

Eddy current types offer faster response, higher accuracy, lower maintenance, and are better suited for dynamic and high-cycle testing.

Still have questions? Want to compare eddy current dynamometer models, prices, or technical support options? Explore our directory or use the contact form to connect with industry experts.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services