Motor testers are used to determine if repairs are necessary and to perform maintenance and troubleshooting in order to minimize downtime and avoid repair costs. A routine test can help maintain the motor’s efficiency so that the lifespan of the equipment will be extended. Read More…

Phoenix Dynamometer Technologies LLC offers the most comprehensive approach to water re-circulation systems, data acquisition systems, and dynamometers in the industry. Along with these high performance products, we also offer business continuity and a competitive advantage for our customers. Come and experience the kind of service that sets us above our competitors. We would love to serve you...

When accuracy, reliability and performance matter look to the name that means dependability: A&D Technology. If you’re looking for an AC Dynamometer or an EC Dynamometer, A&D has you covered! We are a leader in dynamometers and have extensive advantages over other dynamometer manufacturers. Contact us today for more information!

At Magtrol Inc., we specialize in delivering high-precision solutions for torque measurement, motor testing, and force monitoring. Our core strength lies in the design and manufacture of dynamometers that enable engineers and researchers to accurately test and evaluate motor performance under a wide range of conditions.

At MAHA USA, we take pride in engineering and delivering high-performance dynamometer systems that meet the rigorous demands of modern automotive testing and diagnostics. As a team of passionate innovators, we bring decades of experience in precision engineering and mechanical design to every solution we create. Our dynamometers are designed to provide accurate, repeatable results across a wide...

More Motor Tester Manufacturers

Motor testers have a variety of operating procedures to perform electric motor impulse testing, motor rotation testing, wound rotor motor testing, electric motor insulation resistance testing and more. This equipment can operate offline without a power supply or online with applied power and a running motor.

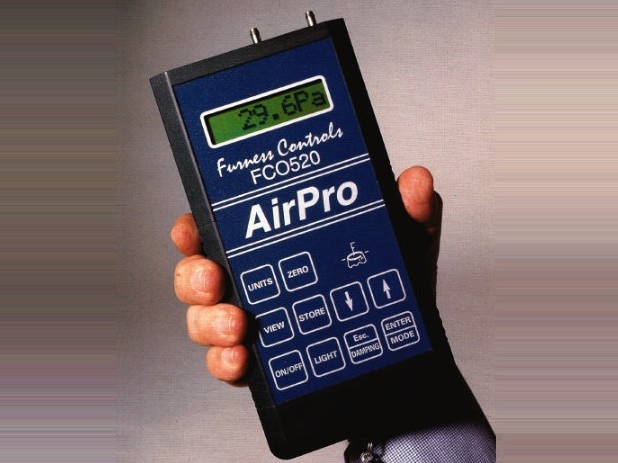

Depending on the application, motor testers may be portable, standalone or installed in the equipment being tested. Because of the widespread usage of both gas and electric motors, motor testers are very important to many industries. Production and manufacturing companies rely on functioning and efficient motors for every process that requires power or motion. These machines may also be used for vehicles.

Motor testers are available in a range of styles, sizes, methods and abilities. Top quality testers perform more complicated analyses, storing and exporting data and graphing it on digital displays. Generally, motor testers work by using voltage probes and current probes attached to input wires of the motor to connect internal voltmeters, ammeters and ohmmeters to the system (only for electrical motors).

Some use a non-contact speed sensor to measure the motor shaft speed and determine the number of rotations per minute. Other options and parameters include a load point test where the motor is tested while under a full load, no load or a locked rotor.

Direction, torque, current, voltage, power, efficiency and cut-out speed may be determined by motor tester equipment because of the range of available options that meet the variety of needs. Much like a torque tester, motor testers may take torque measurements by using a trunnion mounting of the loading device where the brake is mounted so that its enclosure is able to rotate freely around the shaft.

An electronic scale takes the measurements. Transducers coupled with the shaft between the motor and the brake is very fast and accurate with less than 0.1% inaccuracy. For motor power, testers are able to handle speeds from less than one horsepower to several hundred.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

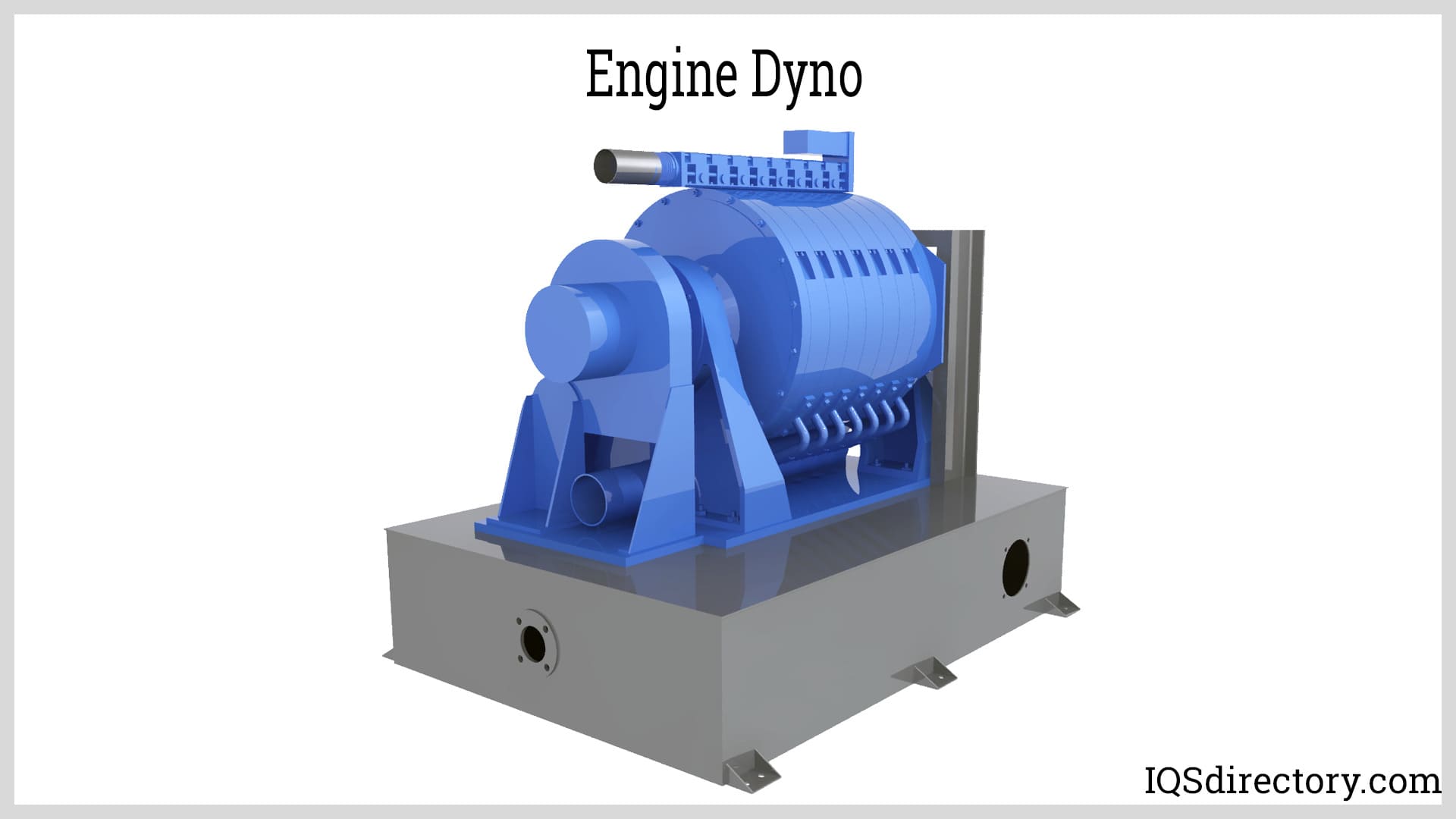

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services